Specially designed for cleaning of oil tanks with large volumes and difficult to clean, the Crude Oil Washing system can be adapted to the individual needs of different clients: it guarantees efficient tank cleaning, sludge separation and oil recovery, all in one process.

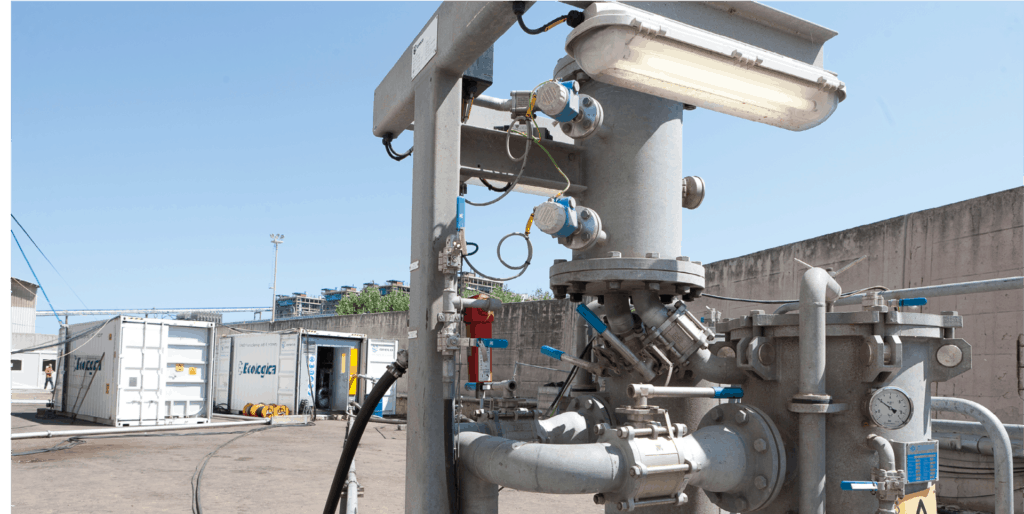

This system can be used to clean crude oil tanks, heavy oil and other types of black oil tanks. It can be used on any type of tank, both floating and fixed roof, and is highly flexible thanks to its modular and containerized structure.

Compared to manual cleaning techniques, the Crude oil washing system cleans the tanks in a much safer and faster way. A distinctive feature is the closed loop cleaning system, which guarantees no emission in the environment atmosphere as well as, thanks to recirculation separation and water wash, the recovery of hydrocarbons up to 98%.

In fact, the oil inside the tank is recovered and transferred back to the client, with a consistent economic and environmental advantage.

| YEAR | CUSTOMER | PLACE | TANK N ° | TANK SIZE | MATERIAL | QUANTITY OF MATERIAL |

| 2012-2013 | Enel SpA Thermoelectric power plant | Brindisi (Italy) | 1 | 100,000 m³ | Orimulsion (bitumen) | 2,500 m3 |

| 2013-2014 | Enel SpA Thermoelectric power plant | Brindisi (Italy) | 1 | 100,000 m³ | Orimulsion (bitumen) | 7,500 m3 |

| 2014 | IES SpA Refinery | Mantua (Italy) | 1 | 60,000 m³ | Crude Oil | 4,500 m3 |

| 2014 | IES SpA Refinery | Mantua (Italy) | 1 | 60,000 m³ | Crude Oil | 2,500 m3 |

| 2014-2015 | Hellenic Petroleum SA Refinery | Athens (Greece) | 1 | 60,000 m³ | Crude Oil | 3,750 m3 |

| 2014-2015 | Hellenic Petroleum SA Refinery | Athens (Greece) | 1 | 60,000 m³ | Crude Oil | 3,500 m3 |

| 2015 | Hellenic Petroleum SA Refinery | Athens (Greece) | 1 | 114,000 m³ | Crude Oil | 11,500 m3 |

| 2015 | Enel SpA Thermoelectric power plant | Brindisi (Italy) | 2 | 50,000 m³ 50,000 m³ | Heavy fuel oil | 1,500 m³ 1,500 m3 |

| 2016 | Enel SpA Thermoelectric power plant | Priolo Gargallo (Italy) | 3 | 50,000 m³ 50,000 m³ 50,000 m³ | Heavy fuel oil | 2,000 m³ 2,000 m3 3,000 m3 |

| 2016 | Enel SpA Thermoelectric power plant | Porto Tolle (Italy) | 3 | 100,000 m³ 100,000 m³ 50,000 m³ | Heavy fuel oil | 3,000 m³ 3,000 m3 1,800 m3 |

| 2017 | Motor Oil Hellas Corinth Refineries SA | AG. Theoodori, Corinth (Greece) | 1 | 120,000 m3 | Crude Oil | 2,500 m3 |

| 2018 | DHAFIR Technologies LLC c/o ADOC Ltd. | Mubarraz Island Abu Dhabi (UAE) | 2 | 12,000 m3 60,000 m3 | Crude Oil | 9,000 m3 4,000 m3 |

| 2019 | Lukoil ISAB South | Priolo Gargallo (Italy) | 2 | 120,000 m3 150,000 m3 | Crude Oil | 2,500 m3 2,500 m3 |

| 2020 | Motor Oil Hellas Corinth Refineries SA | AG. Theoodori, Corinth (Greece) | 1 | 120,000 m3 | Crude Oil | 2,500 m3 |

The Crude oil washing system has several benefits, including:

Reduction of cleaning times

- Up to 80% reduced cleaning time and shorter down-time

- It ensures homogeneous and optimal cleaning of the inside of the tank, thanks to the rotating nozzles

Minimum environmental impact

- It guarantees a recovery percentage of the hydrocarbons present in the sludge up to 98%

- It minimizes the material to be disposed of in landfills

- It limits the emissions of hydrocarbons into the atmosphere thanks to its characteristic closed loop system

- It reduces the consumption of water and electricity

Safe cleaning process

- There is no staff inside the tank during the cleaning

- There is continuous monitoring of hazardous gases inside the tank and working containers

- There is no risk of explosion

- Our system is also equipped with a Nitrogen Generator. In fact, Nitrogen is used during all cleaning operations to keep the Oxygen level inside the tank atmosphere below 8%, to guarantee a safe operation at all times.

- Compliant with ATEX regulations

Economic Advantages

- Shorter cleaning times

- Less quantity of material to be disposed of in landfills

- Less staff needed to carry out the process

- Hydrocarbon recovery

- Profit from recovered oil that can be reused by the Client

COW Cleaning Procedure

Our system is also equipped with a Nitrogen Generator.

In fact, Nitrogen is used during all reclamation operations to keep the level of Oxygen inside the atmosphere of the tank below the 8%, so as to ensure the safety of operations at all times.

The first cleaning phase is the recirculation and dilution of the material present in the tank with a cutterstock (a light oil) used as a cleaning liquid. The recirculation takes place within a closed loop that is created between the various container modules and the cleaning nozzles installed on the roof of the tank, through suitable steel pipes.

To ensure a better quality of the recovered oil, we also use a separation module that includes three-phase decanters for solid / liquid and liquid / liquid separation of the material inside the tank.

The last phase of the Crude Oil Washing system is the washing with water and the skimming between the water and the remaining oil, which is always recovered and returned to the customer.

Once the water wash is completed, the tank is Gas-free and ready for the final manual cleaning of the inert material found at the bottom of the tank.

During this procedure we also use a robot for the final cleaning of the tank roof and walls, to guarantee better cleaning results.

Nowadays the Crude oil washing system is being chosen by more and more clients for its latest generation technology.